How IoT Enhances Cold-Chain Logistics in Singapore’s Food Sector?

IoT integration is transforming cold-chain tracking from warehouse to doorstep:

- Real-time temperature & humidity monitoring via sensors attached to packaging and storage units allow logistic teams to receive instant alerts when thresholds (e.g., 2°C–8°C) are breached.

- GPS-enabled cold boxes relay location data during delivery—so logistics operations can detect detours or delays and intervene before perishables spoil.

- Responsive cooling systems in logistic hubs dynamically adjust storage conditions based on sensor telemetry, lowering food spoilage by 15–20%.

Small businesses like Pine Garden’s Cake report that adding IoT sensors to fridges improved customer trust and reportedly cut ingredient spoilage by 30% .

What Smart Packaging Looks Like Today?

Smart packaging isn’t just insulated boxes—it’s a digital extension of the shelf:

- Time–Temperature Indicators (TTIs): indicators like those from Keep-it Technologies embed labels that signal actual remaining shelf life—outperforming static expiry dates .

- RFID/pH-sensing tags communicate fresh produce acidity in real time—piloted in seafood deliveries and test-marketed in Singapore grocery startups .

- Active packaging uses antimicrobial films and oxygen scavengers to extend shelf life by up to 5 days, per technology demonstrated at NTU with Harvard collaborators .

- Smart QR labels enable consumers to scan for origin, shipping conditions, and “freshness score”—a technology supported by national tracing pilots using blockchain .

Who Benefits? Retailers, Suppliers & End Consumers

- Retailers track freshness in real time, enabling dynamic pricing and reducing markdowns. A local grocer reported cutting waste by up to 25% and improving shelf availability.

- Suppliers can trace temperature deviation back to specific depots or delivery runs—preventing bulk losses and enabling more accountable logistics.

- Consumers gain transparency and reassurance; surveys show over 70% of Singaporeans trust food more when real-time freshness data is visible.

- DTC platforms stream perishable products faster—IoT data helps optimize delivery routes and refrigeration logistics.

Data Transparency: Trust, Traceability & Sustainability

Transparency isn’t just a feature—it’s becoming a strategic asset:

- Blockchain-enabled traceability ensures immutable logs from farm to fridge, allowing full accountability in sourcing and handling.

- Smart packaging data is shared with consumers, supporting sustainability goals by discouraging waste and incentivizing on-time consumption.

- Regulatory pilots are underway that integrate IoT-sourced cold-chain data with NEA inspections, ensuring food safety compliance.

“Consumers won’t settle for ‘best before’ dates. They want real-time proof that their produce is fresh,” notes Dr. Alice Tan, food-tech researcher at NTU’s Institute of Sustainability.

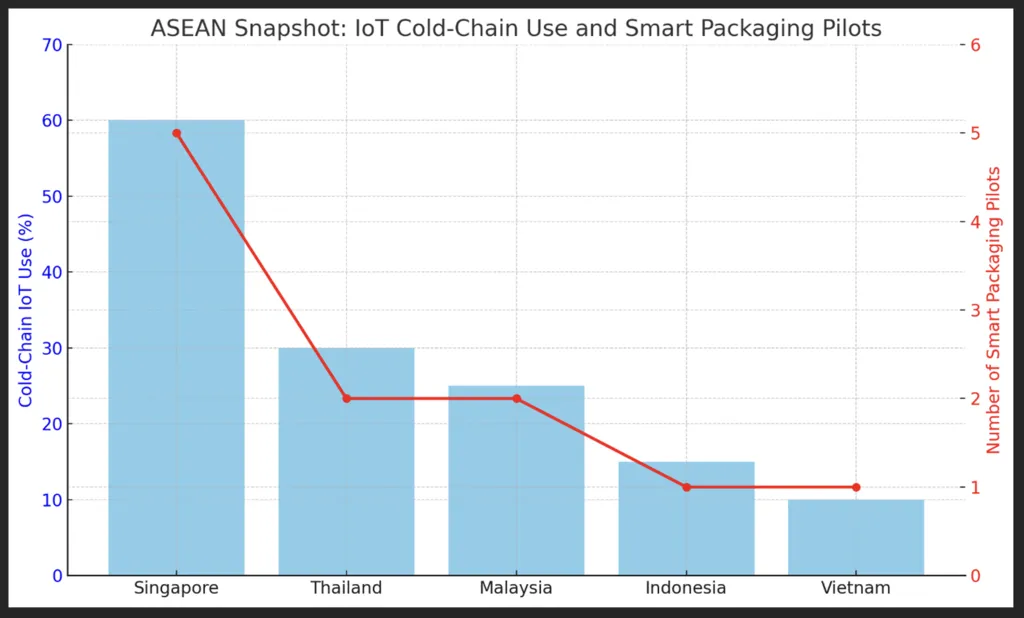

Scaling Across ASEAN: From Pilot to Region

Singapore’s success provides a scalable model for Southeast Asian markets:

- ASEAN nations share similar tropical climates and perishability challenges; IoT cold chain tech is directly transferable.

- Modular pilots like TTI-label trials, blockchain proofs, and sensor deployment in Singapore can be implemented in Jakarta, Kuala Lumpur, and Bangkok with minimal adaptation.

- Regional grants and tech networks are emerging—inspired by Singapore’s PPPs—that support shared logistics infrastructure and packaging standards.

- Early interest from Malaysia’s MDEC, Thailand’s Ministry of Commerce, and Indonesia’s Food and Drug Authority indicates regional momentum for smart cold-chain standardization.

Final Thoughts

Singapore Smart Packaging Cold Chain marries IoT, active materials, and blockchain to foster freshness, trust, and sustainability in food delivery. As the region seeks resilient and consumer-friendly supply chains, Singapore’s approach offers both replicable components and lasting leadership.

Partner with Eurogroup Consulting SEA

We guide retailers, logistics firms, and governments through next-gen food chain innovation—offering strategy, pilot execution, and regional scaling plans. Contact us today to build smart, sustainable food ecosystems across ASEAN.

FAQs

Q1: How does smart packaging reduce food waste?

By using real-time data to pinpoint spoilage risks before they happen, enabling early intervention, dynamic pricing, and precise recalls instead of blanket discards.

Q2: Are these technologies cost-effective for SMEs?

Yes—IoT sensors and TTI labels now cost under S$3 per unit and reduce spoilage losses of 10–30%, enabling rapid ROI in months.

Q3: Can ASEAN countries adopt this model?

Absolutely. Singapore’s modular approach allows easy localization—e.g., Malaysia can start with sensor network pilots, while Indonesia tackles blockchain traceability in seafood exports.